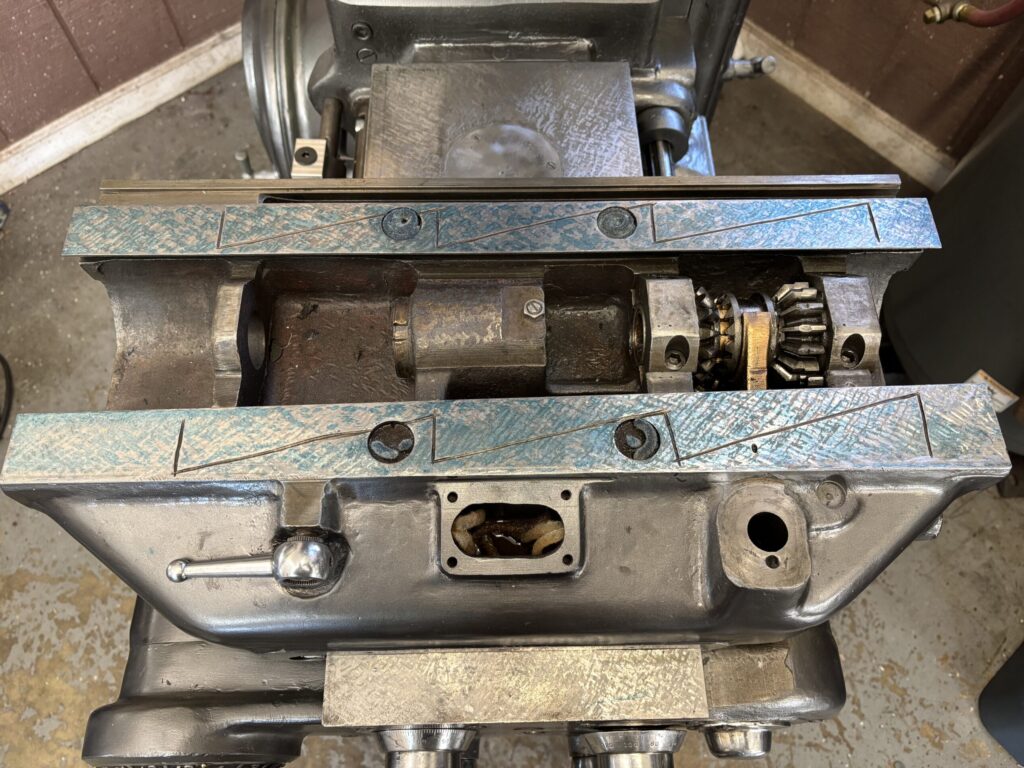

We are nearly done with our Kearney & Trecker 2HL overhaul. Having scraped the top of the knee flat and applied Turcite to the bottom of the saddle, the mating surfaces between the mill table and the top of the saddle now have to be scraped flat and the dovetail ways brought into alignment. As recounted below, this ended up being a chore.

Things started out easily enough. Using a camel-back straight edge and alternating with the glass surface plate, I was able to fairly quickly get the top of the knee flat and the flat ways co-planar to one another.

When the mill was purchased, there were several shims inserted at the bottom of the head, tilting it slightly upward. Once these shims were removed, it was clear that the head was nodding inward in relation to the top plane of the knee by a fractional amount, probably as a result of wear in the ways at the intersection between the saddle and the back of the table.

By selectively scraping the top of the knee I was able to correct this and leave a very slight upward tilt of the knee top to account for sag once the weight of the table was added back. This was checked with the engineer’s square.

I was also able to sweep the saddle across the knee and verify that the top was parallel to the Y axis of travel after scraping the top saddle ways flat.

Scraping Table Bottom Ways Flat

Up until this point, scraping proceeded smoothly. Unfortunately the table ways proved to be in much worse shape than those of the saddle top, with the ends of the table falling off by several thousandths. I had expected a bit of a banana shape, but had assumed that the ends would sag downward when viewed from the top of the table instead of up. Shows you what I know.

Either way, the amount of warp was way more than I could comfortably scrape by hand, so out came the grinder. Having heard horror stories of table dimensions moving once the built up tension in the table surface from years of clamping is broken, I alternated between hand grinding the table surface flat and bringing the ends of the table down. Sure enough, I noticed that it did indeed move on me by a few thou during the process.

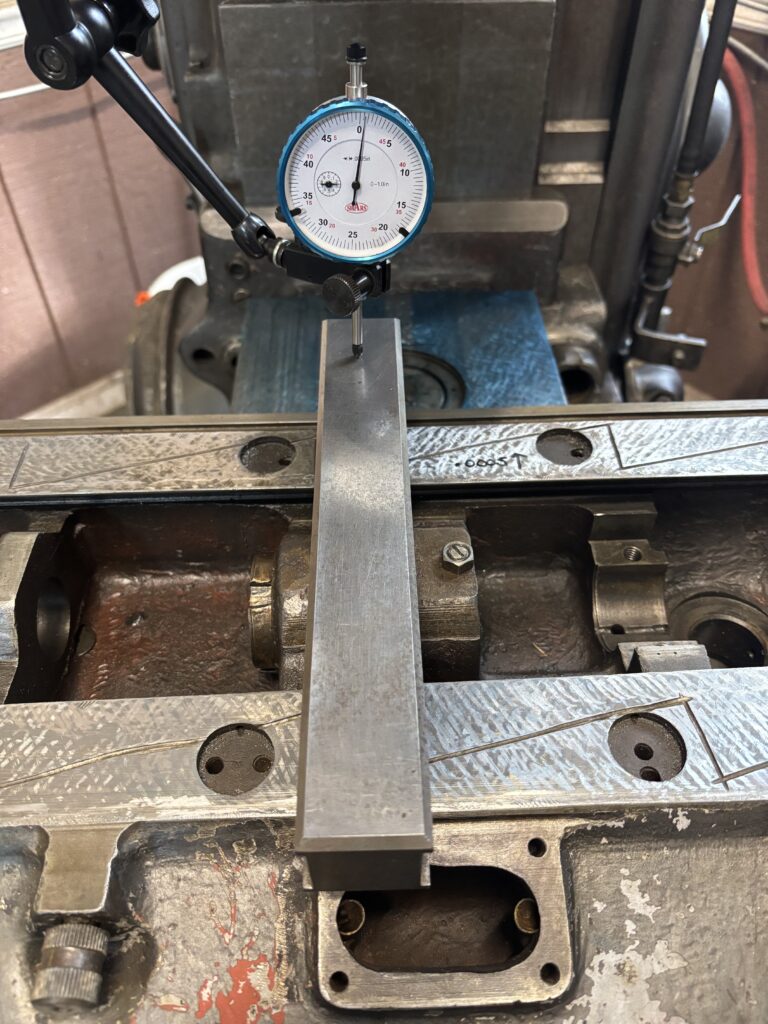

Having ground the ways flat to within 2-3 thou, I finished them up with an interminable number of hand scraping rounds, periodically checking to make sure that the ways remained level and co-planar using a shop made King way alignment tool, an indicator, and a precision level.

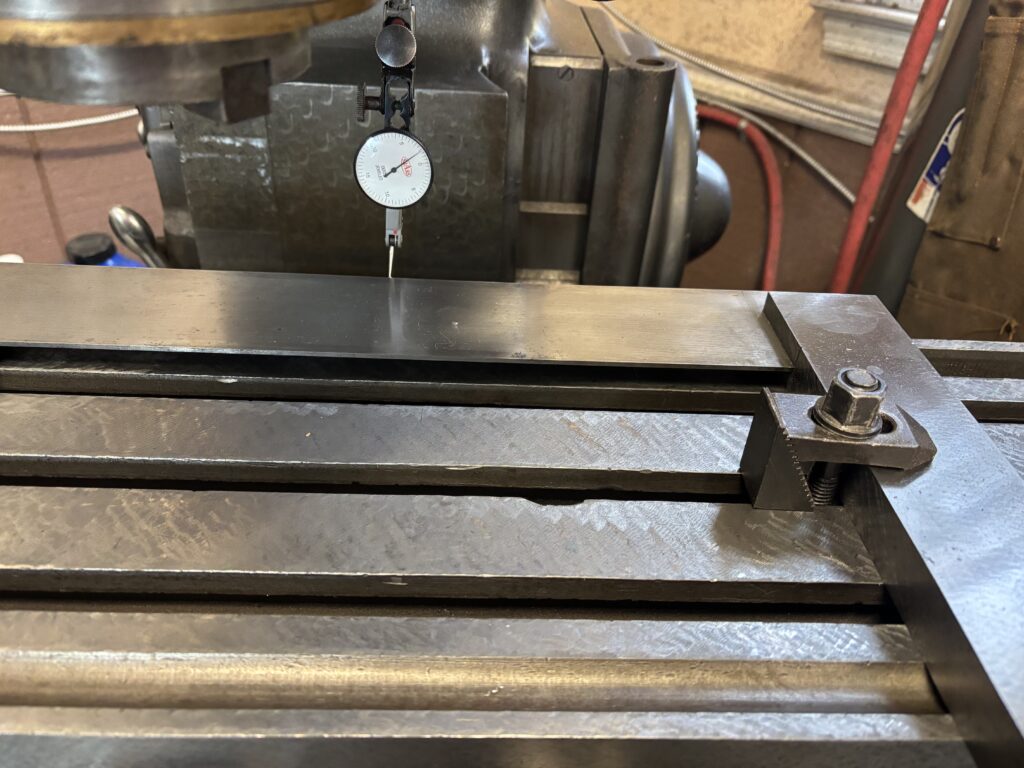

Scraping Table Dovetail Ways into Alignment

Recall, we had originally scraped the knee and saddle dovetail ways so that the saddle’s Y-axis travel ran perpendicular to the reference surface on the back of the saddle. I had expected the table dovetail ways to deviate a bit, but was shocked to discover that when I temporarily reinstalled the table and set my 20” engineer’s square up so that the base was parallel to the Y-axis travel, I was getting almost 10 thou deviation over about 18” of X-axis travel.

What ensued was an endless process of step-scraping the table dovetail ways at the diagonally opposite ends so that the end of the table that was “falling away” from the cutting tool was pulled inward, and conversely pushing out the end that was “rising into” the cutter. In doing this, I discovered that part of the alignment problem could be traced to a slight rocking in the saddle due to unevenly worn ways as well as a slight bow in the Y-axis gib that were both eliminated as the ways were scraped flat. Even so, I’d estimate at least 5-7 thou needed to be taken off the diagonal ends of the table dovetail ways to get the alignment right.

Doing this took about a month of weekend work and was made more difficult by the need to periodically mount and remove the heavy table to check for progress. This was supplemented by regular checks of the ways with a mic and dowel pins to keep the width uniform. In the end, I was able to take that 10 thou movement across the X-axis travel down to nothing with no upward or downward movement of the table in relation to the cutting head. I believe this is as good as an amateur can expect.

I have to confess that there is still a small amount of rocking (about a thou) in the Y-axis toward the back side of the saddle when it is moved to the rear of the knee, but that position corresponds to cutting well off the front of the table. By that point I was sick to death of scraping, so I declared victory.

Next up, and as a final step, we’ll scrape the top of the table flat and perpendicular in both the X and Y axes to the Z-axis of travel. Since we have already hand ground the surface to within about 2 thou of being flat, this should be time consuming but not as much so as our adventure with alignment. After that, I have a very special “cherry on top” finale with a custom DRO setup to preserve the aesthetics of the K&T design while adding some needed functionality. More to come.