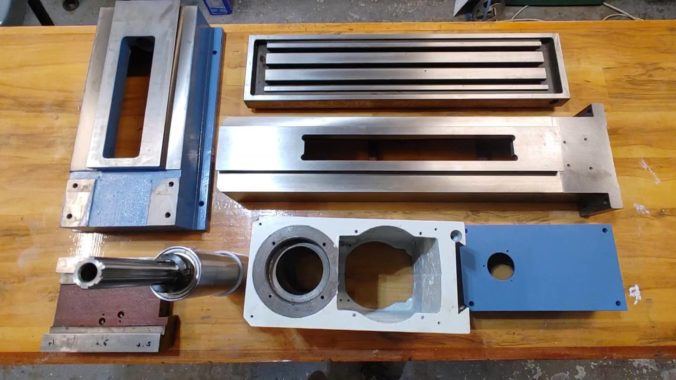

Recall, the plan for the project is to substitute more rigid mill castings for the small X1 at the heart of the BenchMill 6000. At the same time, we want to keep the plumbing, software integration, and all the cool components of the Intelitek machine.

But what substitute castings to transplant?

This was surprisingly hard to figure out. A key design limitation for the project is the need for the new iron to actually fit in the BenchMill enclosure, which provides only 39″ x 28.5″ x 34″ of interior space to work with. On the small end of possibility, I immediately discarded the idea of using an X2 “mini mill”. It would certainly fit, but I would likely be swapping one set of rigidity issues for another.