Time for a new knee mill. My old Wells Index 745 has provided great service, but I’m looking for a new challenge while I finish the CNC project. I’ve been fascinated for a while with the various flavors of American “Heavy Iron” such as Cincinnati, VN, and Kearney & Trecker. Now … drum roll … I have one to play with.

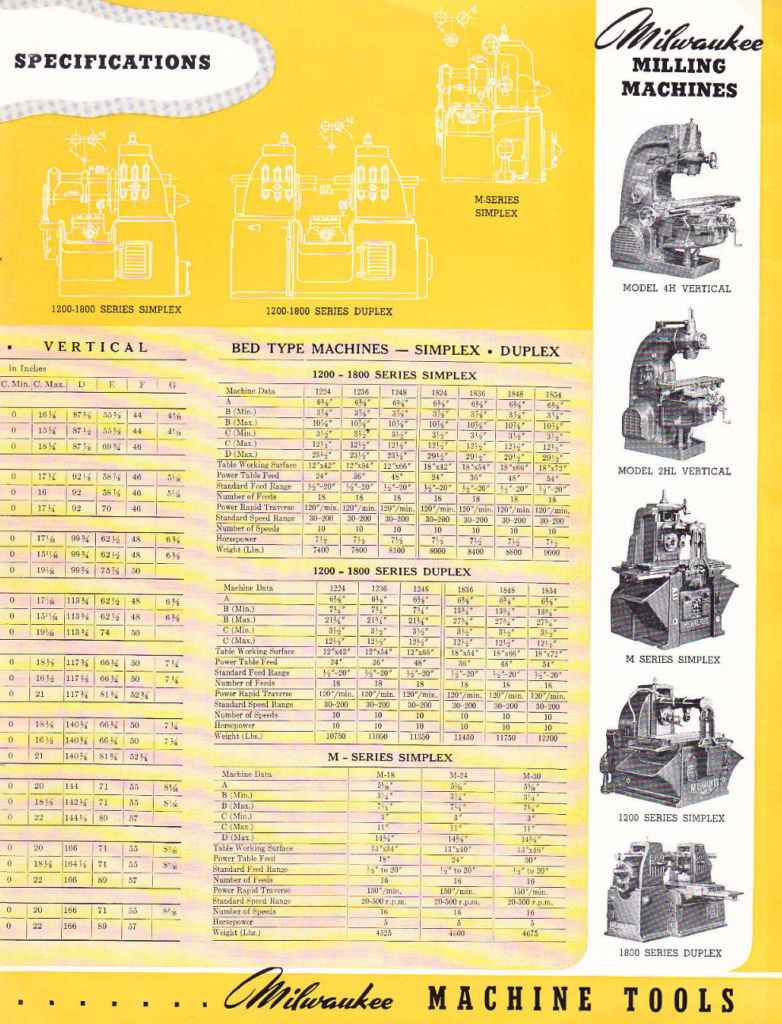

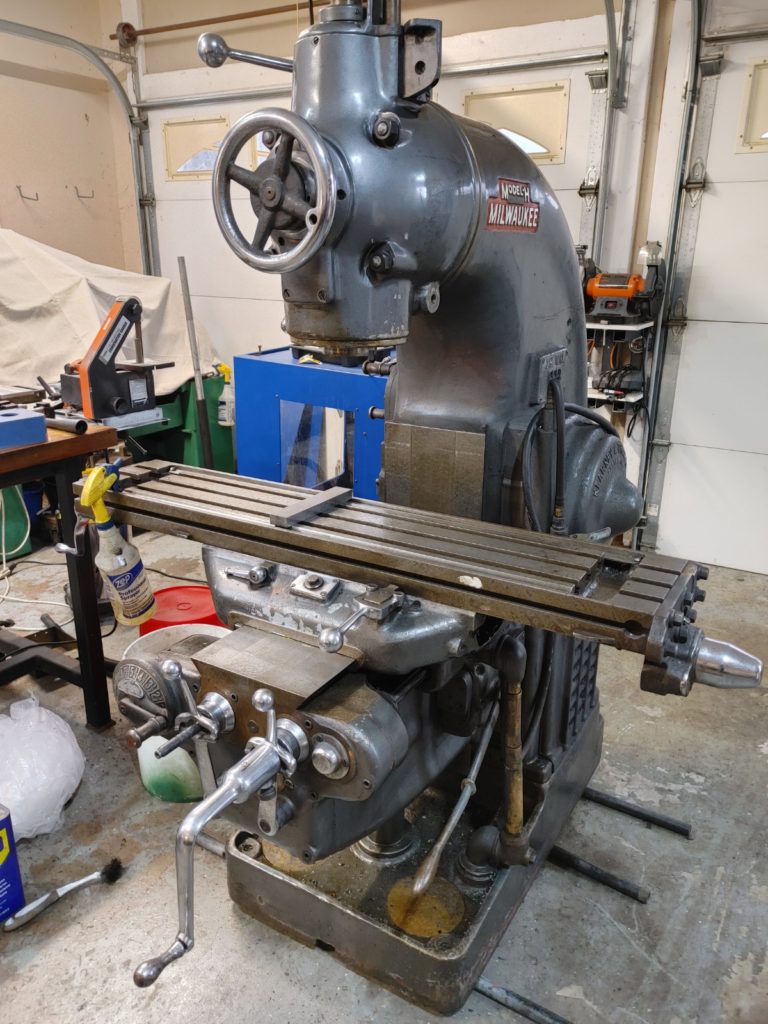

Down South, you’ll occasionally run across examples of these machines, but many of them have seen MUCH better days, and others are just too damn big for hobbyist use. That is why I was excited to see a working K&T Milwaukee 2HL “swivel head” vertical mill go up for auction in South Bend, Indiana. Not looking forward to a 12-hour drive I put in what I thought was a fairly low bid for a running example and … got it.

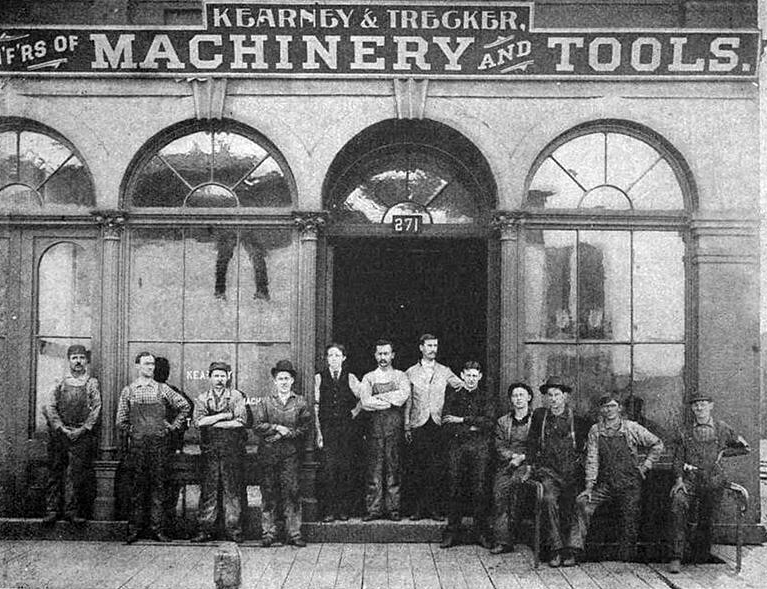

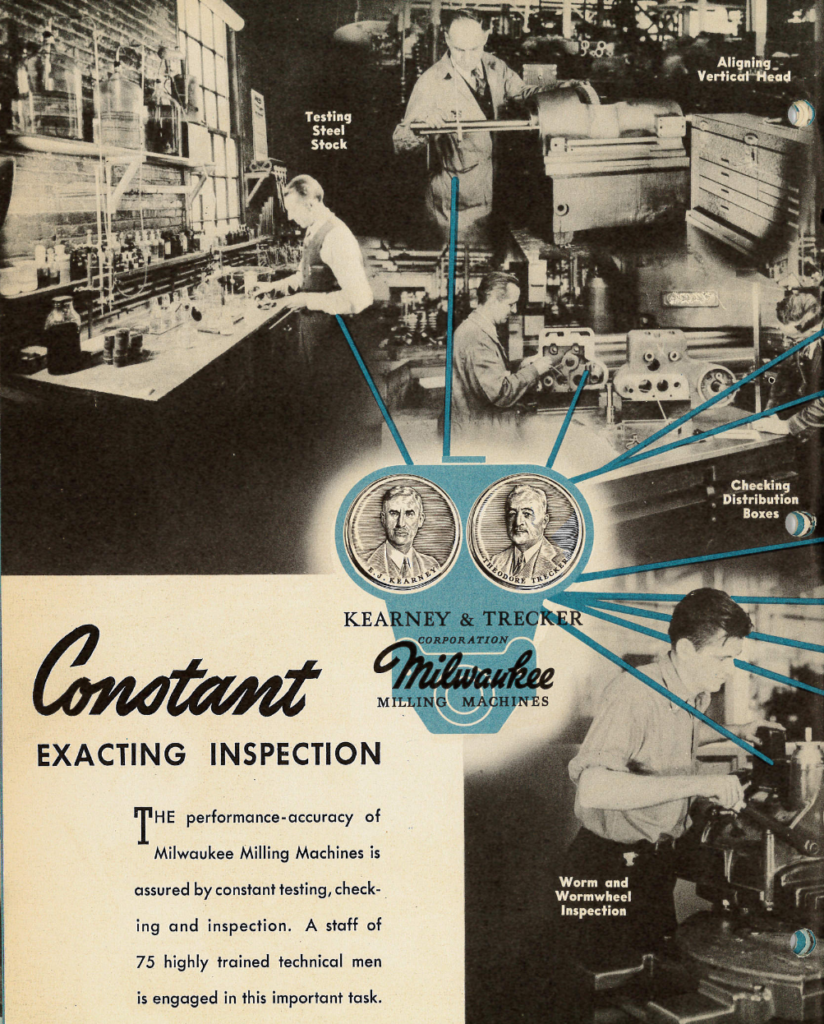

For those who are not familiar, Kearney & Trecker was founded in 1898 and began manufacturing milling machines when, according to the story, the founders were not allowed to purchase a Kempsmith machine.

At one point K&T was the largest milling machine manufacturer in the world. Based in Milwaukee, their 20th century machines arguably represented the pinnacle of mechanical milling machine design. The Model 2H, upon which the 2HL I purchased is based, features power feed and rapids on all three axes, all driven by internal shafts and gears. They are not necessarily better than other American brands of the era, but they sure are elegant.

A lot of the K&T Milwaukee mills you see for sale in the South are horizontal, so I was doubly interested to see that the one for sale was a vertical “swivel head” example. Weighing in at a svelte 3,300 pounds, the mill, believe it or not, is a “light” model.

The trip to South Bend was uneventful. Given the weight, I hired a rigger to load the mill on the drop deck trailer I rented for the trip. Word to others contemplating a heavy mill move — go ahead and use a drop deck trailer. They make the process of getting the machine off soooooo much easier.

Despite the weight, with the deck lowered to ground level all I needed to get the mill off was a winch and a hoist to make it easier to lever the base up on iron rollers. After a lot of push and pull, I was able to get it inside, where it now sits.

The plan is to change all the fluids and get the machine running on 220v power with a VFD. I’ll then diagnose issues and map out a plan of action for the restoration. I need a working knee mill to finish my CNC project, so my initial efforts will be to restore functionality before breaking it down for what I expect to be 6 months of hand scraping…