From our initial diagnosis we know that our Kearney & Trecker (Milwaukee) 2HL Vertical mill has issues with power feed at any speed over 7 or so inches per minute. To figure out what is going on, we’ll need to remove the front of the knee and disassemble the feed distribution gearbox. I won’t go into too much detail since there is an excellent video already out there, but there are a couple of key points I can reinforce here.

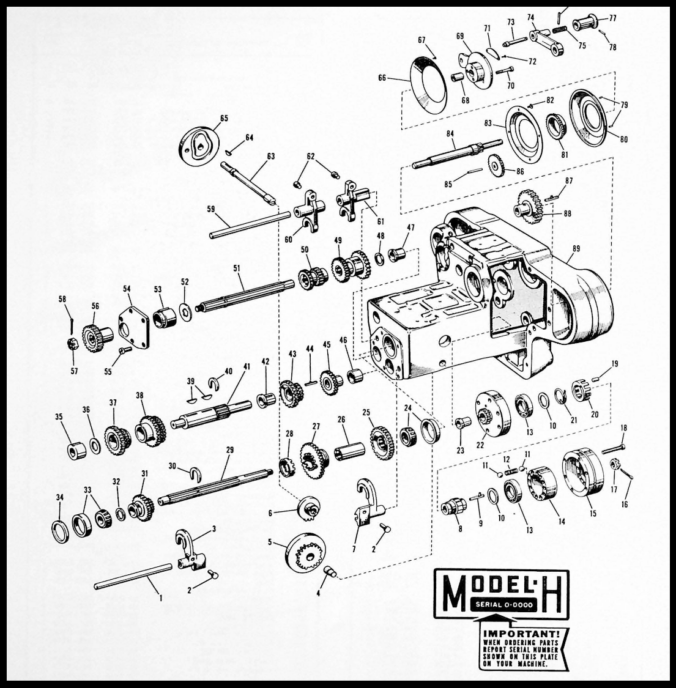

Most of the preparatory work to remove the box requires work on the left side of the mill, where there is a small right angle feed change worm gearbox (#9 in the parts diagram below the fold). It is held in place with three slotted screws. Before removing it, best practice is to go ahead and set the feed to the lowest setting to simplify the feed timing when the feed distribution box is reinstalled (see discussion below).

Next, we’ll need to remove the trip dogs (#52) that ride on the vertical and cross feed rods (#55 & #53). These are each held on by a cap screw and slide off to the rear. In my case, some previous jackassery had resulted in one of the cap screws being positioned such that it rubbed on the underside of the saddle. I’m not sure if this was what was throwing off the Y-axis precision as the table was cranked out, but I’ll be keeping my eye on this possibility.

Continue reading