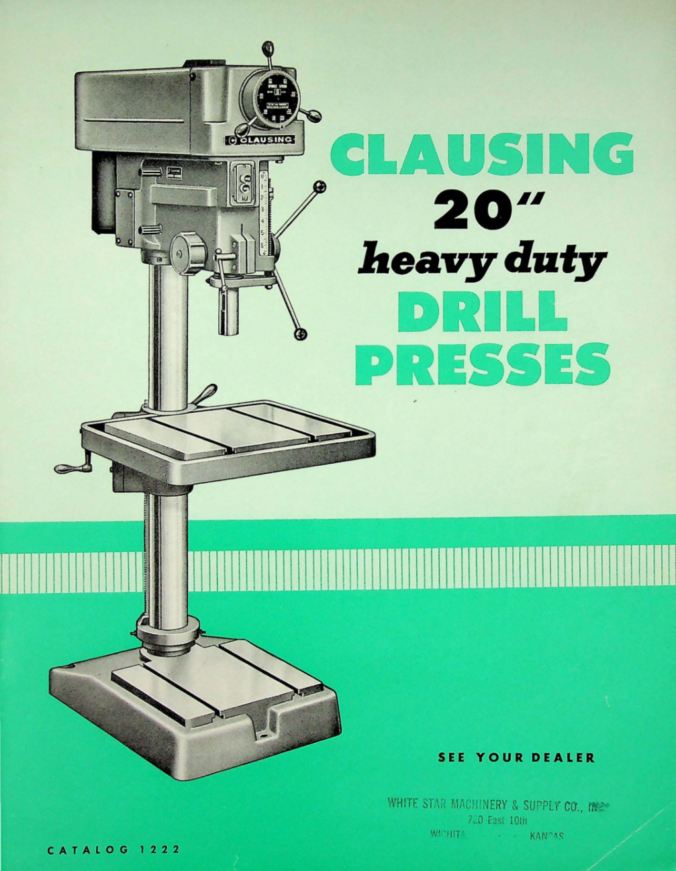

Having replaced the spindle bearings and fixed the issues with the Reeves drive intermediate shaft of the Clausing 20″ drill press, it is now time to reassemble the machine and put it into service. While they were apart and everything was disassembled, I degreased all of the castings and gave them a coat of KBS Coatings “top coat” in battleship grey (which really turned out to be more of a grey-blue). Even though the color wasn’t what I expected, it has grown on me.

Cleaning up the 4″ center column was a bit more of a chore. Thirty+ years of grime and surface rust left it severely gummed up. After struggling with a brush and various cleaners for a while, I decided to just chuck the column up in my LeBlond, supporting the far end using a steady rest. I then set it to a few hundred RPMs and attacked the grime with green scotch brite pads and mineral oil. It worked a treat. In the future, I wouldn’t tackle this job any other way.

Continue reading