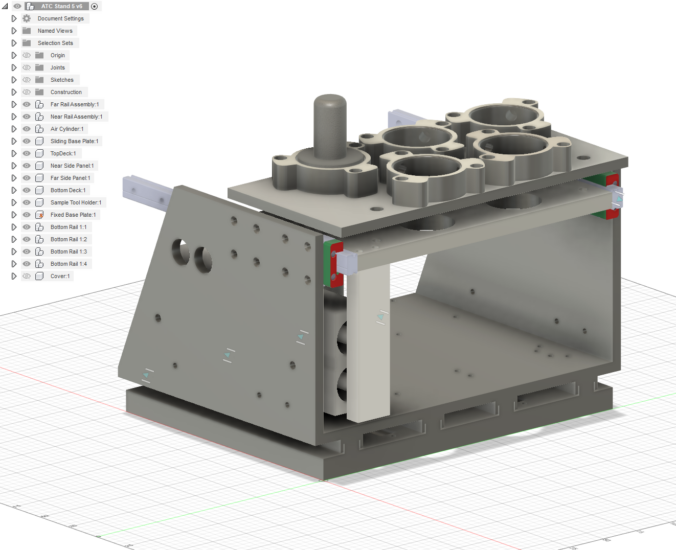

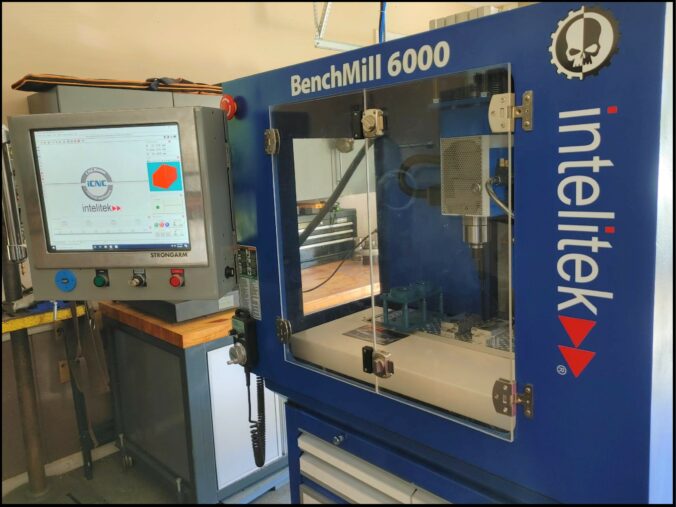

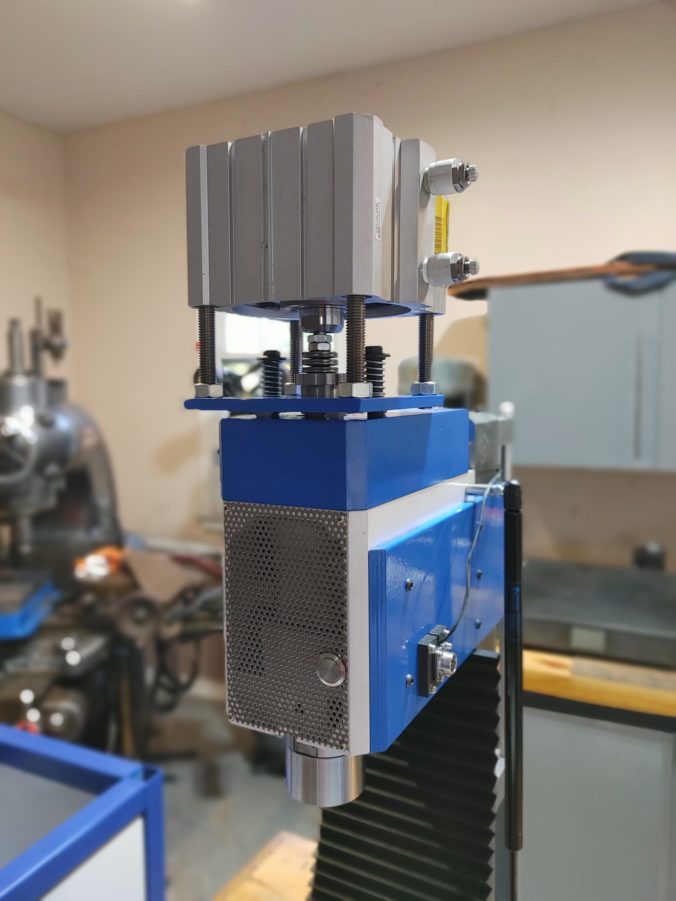

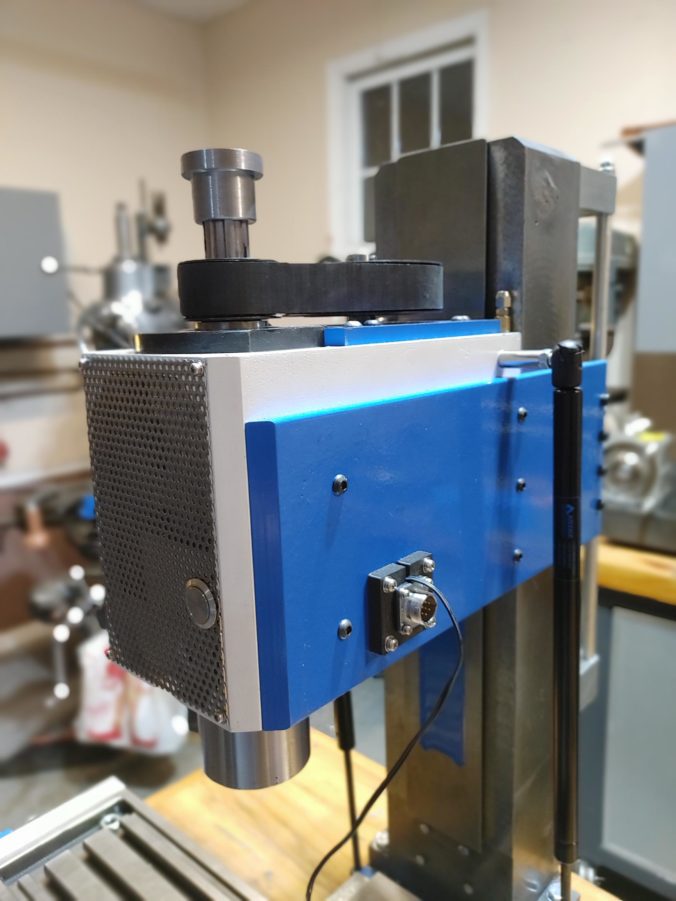

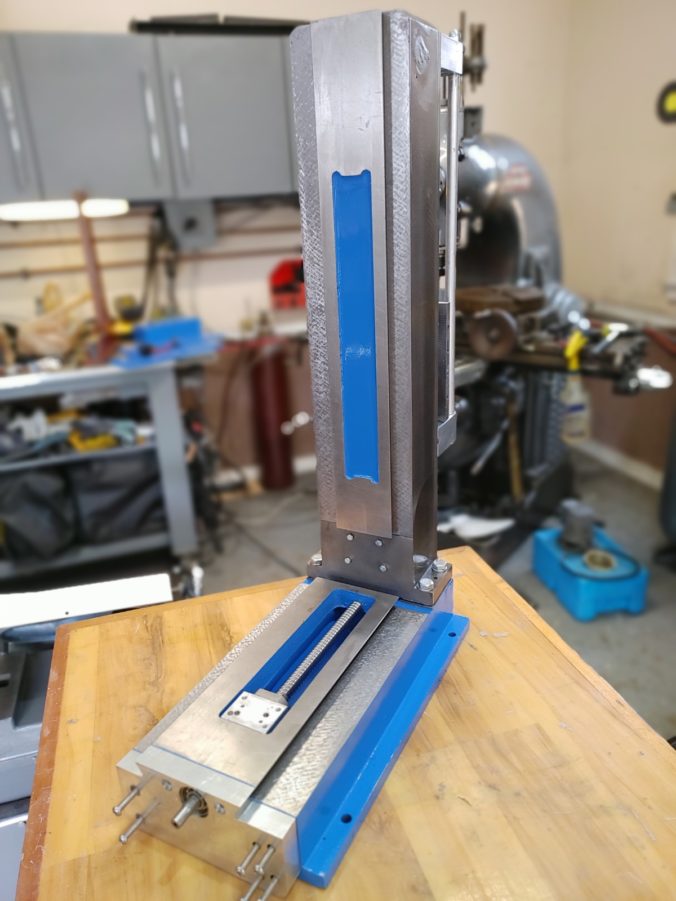

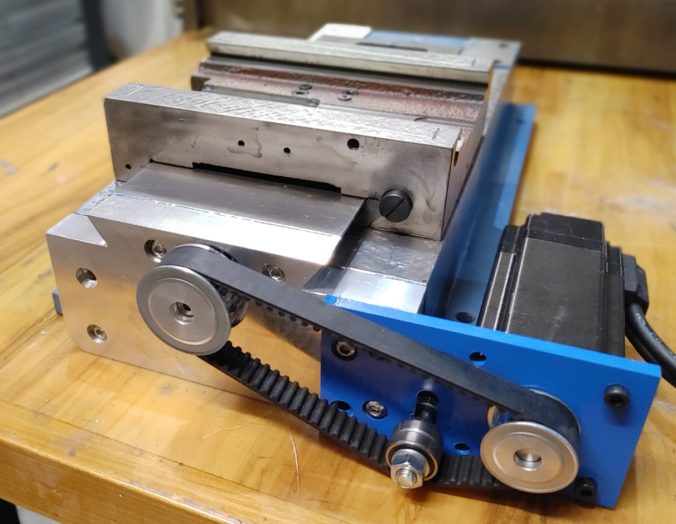

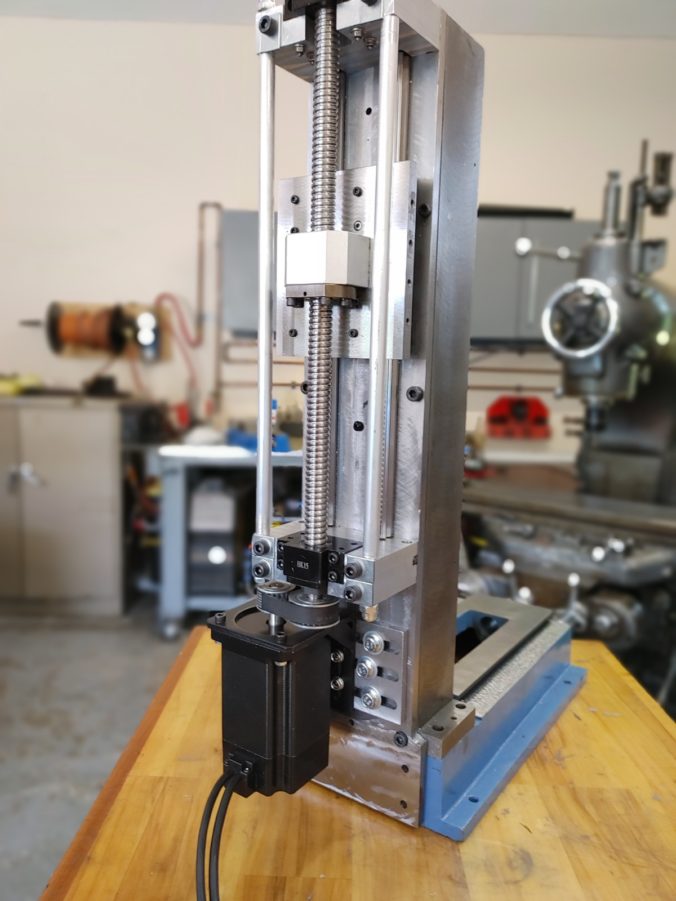

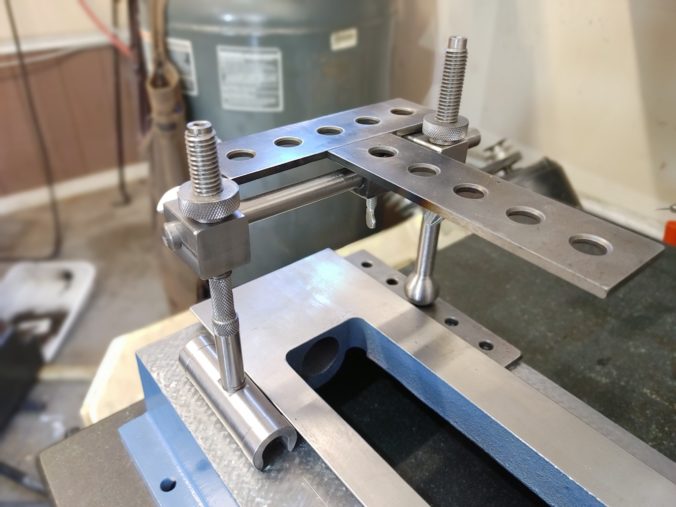

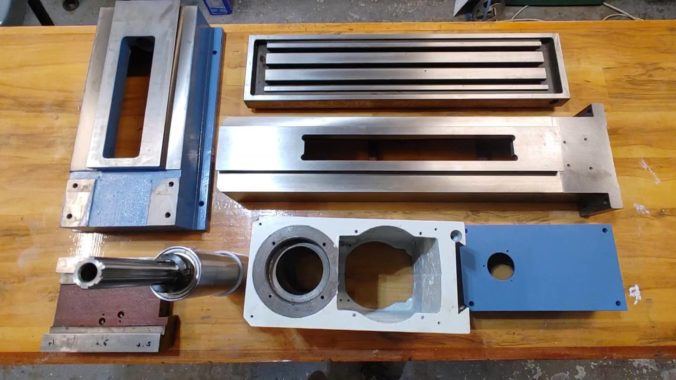

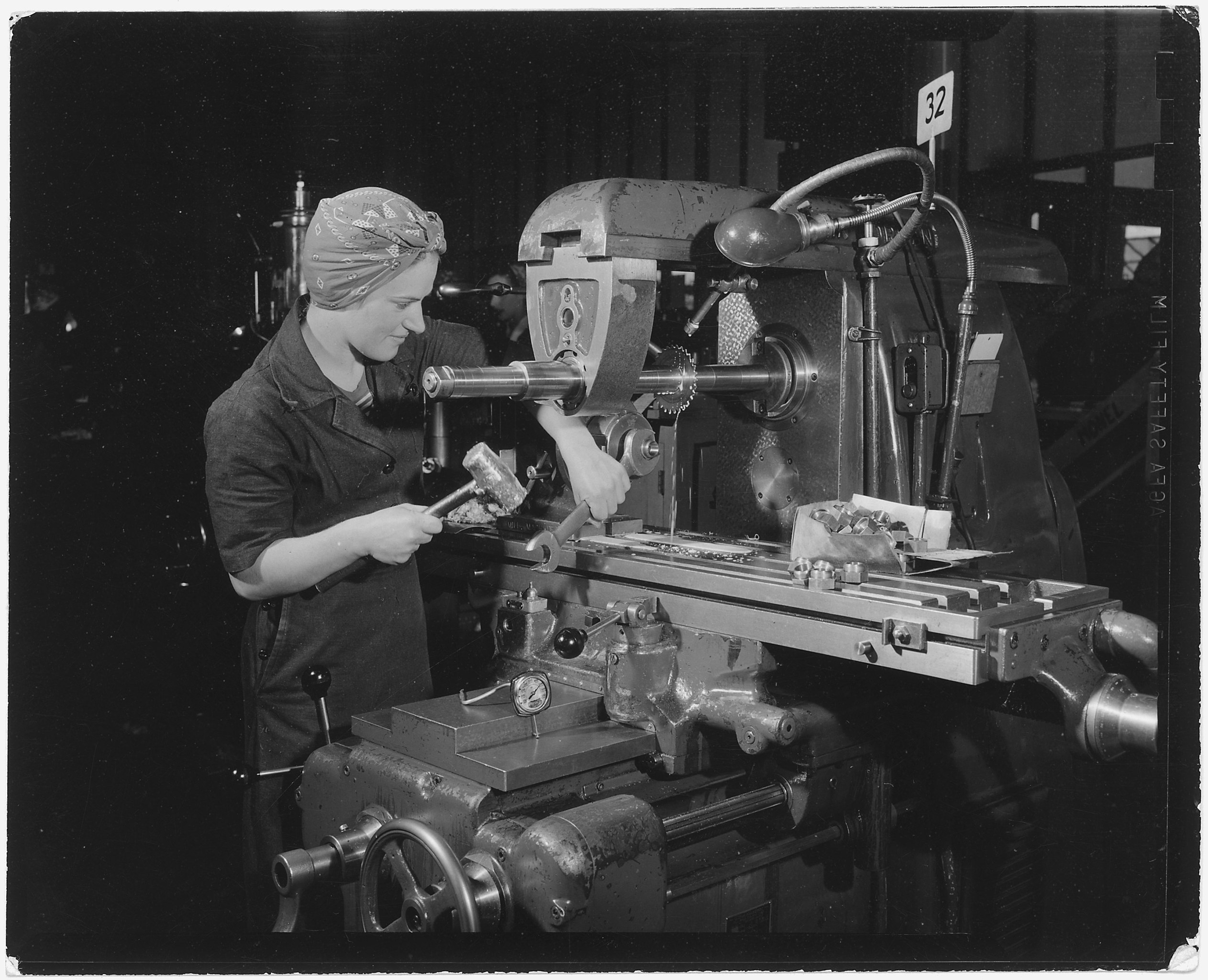

We have more or less completed our Benchmill CNC upgrade project, installing Sieg 2.7 castings in place of the original mill, reinforcing the head, upgrading the power distribution, and installing a 2 HP spindle motor. We have the auto-oiling and pneumatic power drawbar installed, and everything is up and running. As icing on the cake, we are going to take advantage of the Intelitek automatic tool changer functionality built into its CNC software to support a scratch-built sled-style automatic tool changer system.

In designing an ATC system, there are a few options to consider when getting the tool to the spindle nose. The most common approach is to use a rotary carousel where an indexed platter holds the tools. This platter rotates to predefined positions to call up the requested tool, which is then clamped into the spindle using various design-dependent mechanisms. Digging through the config files for the Intelitek software, I saw that it does in fact include settings for a rotary tool changer, but that functionality is associated with a different model (Promill 8000). Rather than run the risk of building something only to find missing wiring connections into the controller that the software assumes are present, I elected to go with a more simple sled-style design.

Continue reading