Over the last year or two, I replaced the abrasive wheels on my 8″ no-name bench grinder with a brass wire wheel and a nylon fiber deburring wheel, both of which I found I used much more on a day-to-day basis. Still, I do need to grind down welds, shape the occasional HSS lathe tool, and sharpen larger drill bits from time to time, and was getting sick of swapping out bench grinder wheels when the occasional grinding job presented itself.

The original plan was to buy a second, quality made bench grinder … maybe even a 10″ model … and devote it to actual grinding. However, the good bench grinders seem to be caught up in the post-COVID inflation spiral (or maybe they were always this expensive, I dunno), but for whatever reason the cost of a decent new grinder didn’t make a lot of sense for my situation.

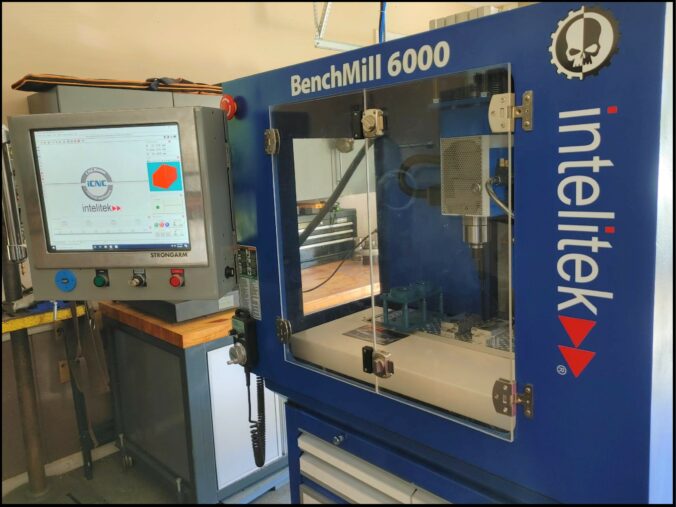

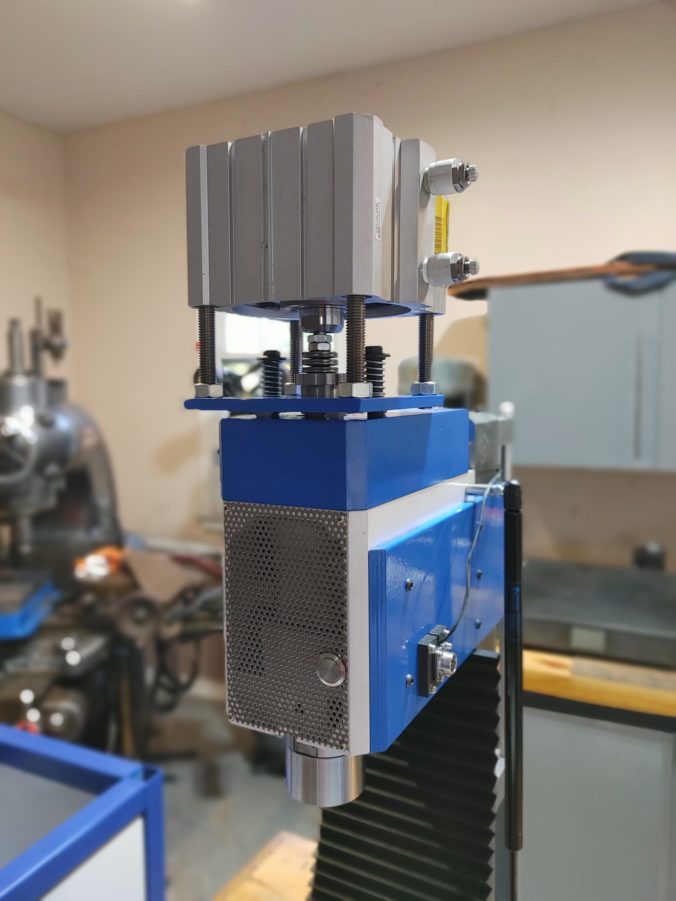

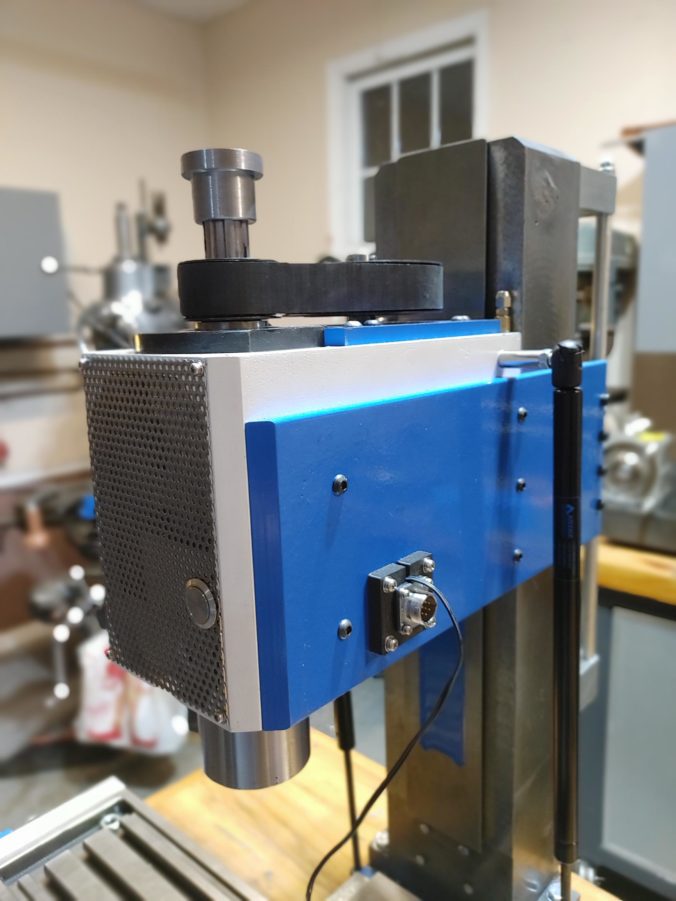

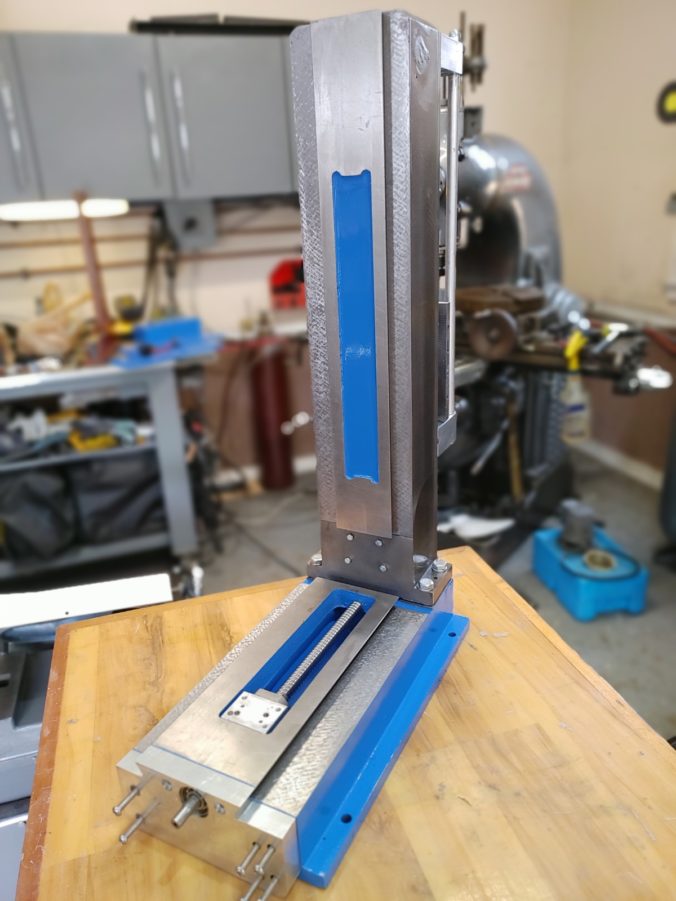

As a “Plan B”, I began monitoring local equipment auctions, as one does, and as luck would have it, found a ratty looking Queen City 12″ grinder at a nearby auction in Dallas, Georgia. I ended up getting it for the princely sum of $120 and got it home without incident … where it sat for most of the next year. With my CNC project finally done, and before launching into the Kearney & Trecker 2HL mill rebuild, I thought I’d clean up the Queen City grinder and get it operational.

Continue reading